Our eco-extraction technology

Innovation for tomorrow’s world

Our innovative eco-extraction technique

Antofénol innovates with its unique technique: a hyperfrequency eco-extraction process allowing production on an industrial scale, quickly and without chemical solvents. This unique and natural process makes it possible to develop effective, sustainable, environmentally and health friendly solutions for the agricultural, cosmetics and food markets.

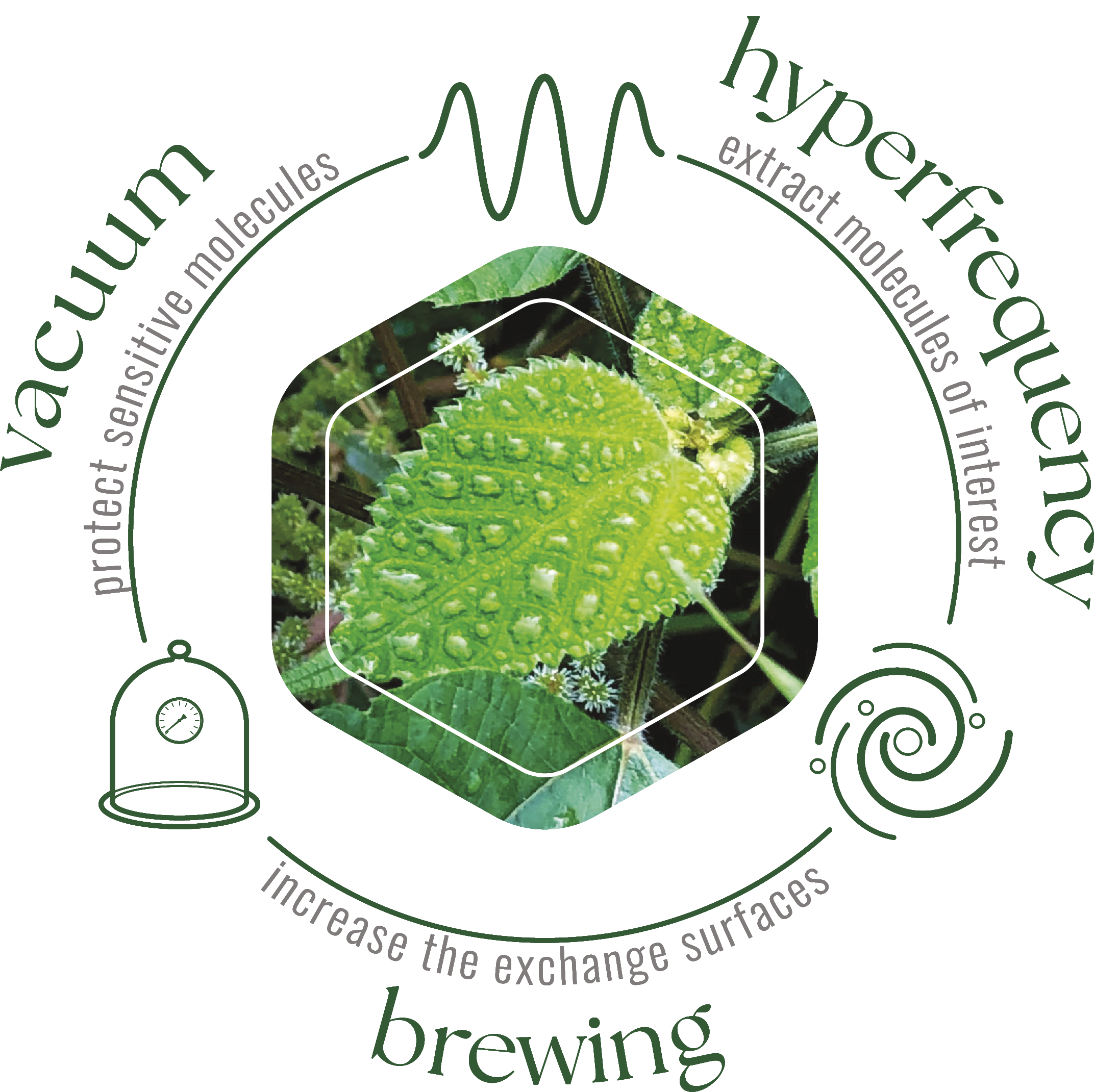

Applicable to all types of plants, our technology combines hyper frequency, vacuum and brewing in a single process.

Hyper frequency waves are applied directly on the plant material. These waves generate molecular agitation, causing heating within the core of the plant cell, enhancing the extraction process for both efficiency and naturalness by eliminating the need for chemical solvents. Brewing homogenizes temperature gradients and increases the exchange surfaces between the material and extraction medium.Vacuum protects molecules sensitive to oxidation.

We use a 32 L pilot extractor paired with a 2.5 kW microwave generator for conducting extraction laboratory-scale tests. Additionally, we employ two industrial extractors, sized at 450 L and 1050 L respectively, equipped with a 75 kW microwave generator to facilitate larger-scale production.

Laboratory scale extractor

- Capacity: 32 L

- Microwaves power outpout: 0.5 to 2.5 kW

- Brewing: 0 to 100 rpm

- Vacuum: 400 mbar

- Vapors condensation: 20°C

- Temperature control by cooling the tank envelope to 20°C

- Hyperfrequency waves and raw material compatibility check

- Extraction parameters optimisation

- Formulated or freeze-dried extract production

Pilote scale extractor

- Capacity 450 L

- Microwaves power outpout: 15 à 75 kW

- Vacuum: 150 mbar

- Vapors condensation: 30°C à -20°C

- Temperature control by cooling the tank envelope to 8°C

- Check of process compliance and adaptation of processes to industrial constraints

- Realization of the tested product: hydrodistillate, essential oil, native water, concentrated extract, formulated extract, powder

Industrial Scale extractor

- Capacity: 1050 L

- Microwaves power outpout: 15 à 75 kW

- Brewing: 0 to 15 rpm

- Temperature control by regulating the tank envelope for cooling and heating from 8 to 100°C

- Nitrogen inerting

- Production of finished products in large quantities: native water, concentrated extract, formulated extract, powder