Antofénol is firmly committed to ecological transition through its construction of a zero-waste factory

1 December 2022

‹ Previous post

Antofénol – new technologies for a greener tomorrow

Next post ›

Antofénol is firmly committed to ecological transition through its construction of a zero-waste factory

Extracting nature’s bounty with an eco-responsible circular economy approach is the philosophy that has inspired Antofénol since its creation in 2014. We have developed innovative technology that offers various industries the opportunity to include natural active ingredients in their formulas. This proven innovation is developing to its full potential in the cosmetics sector. Discover how plant eco-extraction draws active ingredients from the plant’s core to form the functional ingredients of many cosmetic products and why these concentrated active ingredients are so important for the cosmetics industry.

We have developed a unique and innovative eco-extraction process to provide our customers with plant extracts that are rich in useful molecules. Its unique feature is that it does not require any chemical solvents. By combining three plant extraction processes within the same equipment, we have been able to open up the plant fibres in order to release the useful molecules and extract all the compounds.

The advantages of this type of plant extraction are significant, not least the ability to dispense with chemical solvents that are harmful to health and the environment. As part of a sustainable development approach, Antofénol’s plant-based eco-extraction reduces the energy consumption required to produce the functional ingredients that are so useful to the cosmetics industry. We have also developed our process into a circular economy: we reinvest the waste generated by extraction into production. The extraction time has been reduced to between 30 and 60 minutes, which is considerably less than other processes.

Antofénol’s eco-extraction opens up a wide range of possibilities for producing all types of extracts, fully adapted to our customers’ needs, particularly dry or liquid extracts, in oil form, natural floral water, hydro distillate or essential oils. We work with selected raw materials to obtain these plant extracts, using all types of biomass, and including flowers, wood, fruit and roots. Our technology is not limited to one type of biomass but can process a very wide range of plants.

Our innovative eco-extraction technology is available as a bespoke service for industries requiring large quantities of natural plant extracts, like the cosmetics industry. We carefully select the plants we use as raw materials before classifying the plant extracts and making them available to our customers. See the various stages of our customised service.

We work with the customer to draw up a set of specifications based on the market in which the brand operates, its challenges and the target molecules. The appropriate extraction protocol is determined in order to obtain the plant extract that best meets the final needs.

The raw material is then selected and secured: material can be sourced in France and internationally, in particular, through our Asian-based unit, Socanto. We have access to a network of partners around the world, particularly in Africa and Europe.

Plant-based eco-extraction is not immediately implemented on an industrial scale. The plants are first processed in the laboratory to check the feasibility of the process and to optimise the extraction protocol to achieve the optimum settings. When the required quality is obtained, the plant extract for cosmetics is then classified.

At this stage, the different extracts are biochemically classified according to their origin, harvest year or variety. Thus, the most suitable plant for the customer’s needs is selected and approved on site at the place of cultivation. Thanks to our analytical capabilities, we are able to closely examine the properties of the extracted molecules. The biochemical structures of the active compounds are clearly identified.

This is where we precisely measure the biological activity of the molecules on the target. Through our network of partners, we can screen biological activity on a genomic chip, on skin explants or through metabolomics. As a result, our customers will be able to build a strong scientific case for the objectivation of their ingredient. The different functions for which the extracts are produced are checked and approved.

Once the project’s feasibility has been approved and its effectiveness verified, the plant extract is ready for industrial production prior to its integration as a functional ingredient in the customer’s final cosmetic product. Our factory is able to adapt the production process to fit the requirements, from a few kilos of dry extract to several dozen tonnes of liquid extract. Again, traceability and quality control are guaranteed at all stages.

Antofénol has installed state-of-the-art machinery to extract valuable substances from the plant. The unique extractors developed by the Antofénol teams combine three extraction processes for a particularly concentrated result. By combining microwaves, vacuum and agitation, we are able to extract useful molecules from selected plants and agricultural co-products.

Our laboratory is equipped, in particular, with a 32 L pilot extractor which operates with 3 kW microwave power. It extracts the useful molecules, providing continuous temperature control and the ability to create a vacuum down to -300mbar. This extractor is used for the first extraction. It then gives way to a 450 L industrial extractor with 75 kW microwave power.

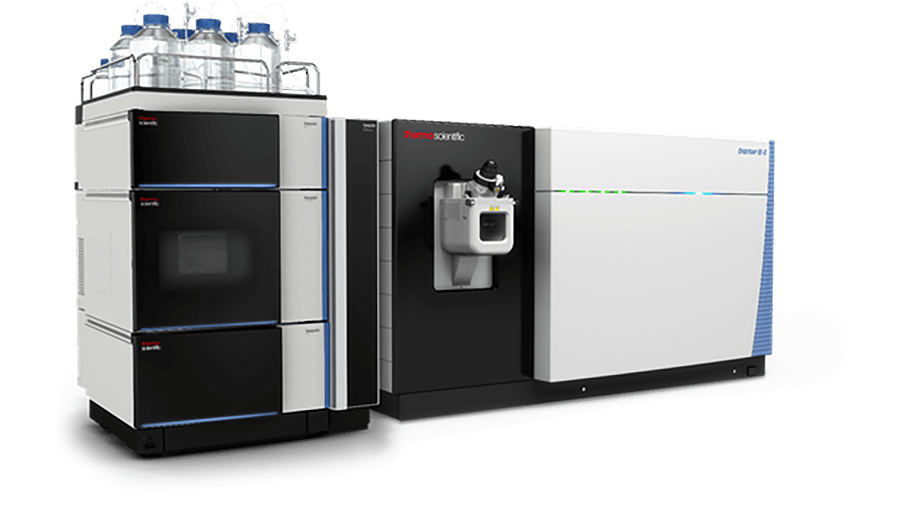

For classifying our plant extracts, our laboratories are equipped with an HPLC device and 2 UPLC (Ultra Performance Liquid Chromatography) devices that are used to separate the different substances present in a mixture. Our Orbitrap ID-X mass spectrometer detects the complex chemical structures in our extracts, clearly identifying the individual compounds. This tool adds value to the product extracted, for example, as a basis for a registration application. . The Orbitrap ID-X analysis can also be used to determine biomarkers, which are useful for production control. Different extracts can thus be objectively compared according to their phytochemical profiles.

Eco-extraction is particularly relevant as it offers the cosmetics industry active ingredients that can be extracted without using chemical solvents. With this unique and innovative technology, Antofénol has positioned itself alongside brands in their desire to offer more natural and concentrated products to consumers. As a true eco-extraction developer, we are supporting the cosmetics sector in its eco-responsible journey. Cosmetics companies can now access high-quality plant extracts and offer their customers effective and environmentally-friendly products through Antofénol.