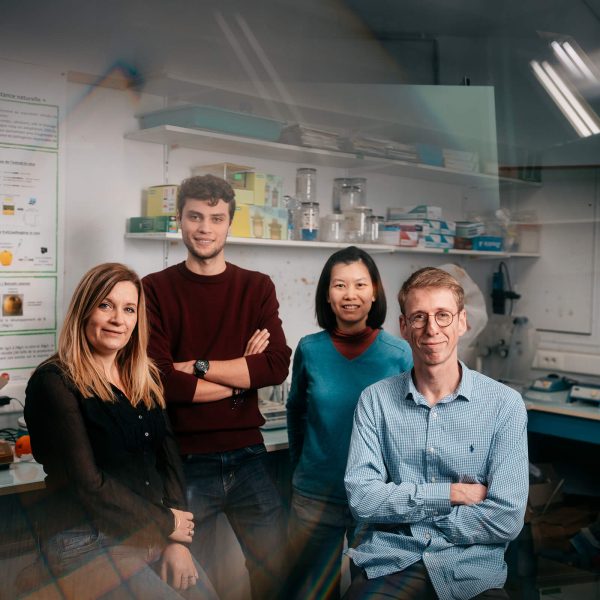

Antofénol – a team committed to a greener tomorrow

26 January 2023

‹ Previous post

Antofénol – new technologies for a greener tomorrow

Next post ›

Antofénol – a team committed to a greener tomorrow

At Antofénol, we have a profound respect for the environment and innovation built into our DNA. As the creators of eco-extraction, we are now taking the next step and industrialising our chemical-solvent-free process on a large scale. We are about to begin construction of a new building. We are continuing our commitment to ecological transition in the town of Le Thor in the Vaucluse region. Come with us to our new zero-waste factory, where we will continue our mission of procuring the best that nature has to offer.

The Saint-Joseph Ecopark in Le Thor is the installation site for Antofénol’s new eco-extraction tanks. And the site wasn’t chosen at random. With the support of Vaucluse Provence Attractivité, our company was able to find the ideal location for industrialising our eco-extraction process. The two plots of approximately 4,500 m² each will accommodate our new factory of over 6,000 m² which will be used exclusively for our unique technology. But why did we decide to set up in this area? Even if it was the view of Mont Ventoux that finally won over our CEO, Fanny Rolet, she also recognised that this location offered considerable advantages for Antofénol’s future development.

Investing in a wine region was the primary criterion when looking for a location. There is no shortage of wineries in the Vaucluse region and this concentration of winegrowers ensures a sustainable and ecological supply of the raw material for one of our flagship eco-extraction products, antoferine. The cuttings generated by pruning the vines represent 86,000 tonnes of potential raw material, only a short distance from the factory, forming a planet-friendly supply chain.

The Vaucluse region has a thriving plant processing ecosystem. Located in the heart of a major production area for aromatic plants, the region provides a dynamic and supportive environment for our laboratories’ activities. In addition, it offers specialised training in biotechnology, which will create a pool of potential applicants for future recruitment drives. Antofénol will thus benefit from Southern France’s considerable appeal in order to expand its workforce.

Construction is expected to start during the second quarter of 2023, with completion scheduled for the second half of 2024.

Driven by our commitment to the planet and our passion for conserving resources, we wanted to make our factory as environmentally-friendly as possible. And we have achieved our goal. The Antofénol factory in Le Thor will be a shining example of environmentally-friendly production on an industrial scale.

In order to finance the construction of our new factory, we have teamed up with partners and investors who are just as committed as we are to the great project of ecological transition. Initially, it was beyond France’s borders that Fanny Rolet, our founder, was able to convince people about her ambitious and innovative project. As a 2019 recipient of the EIC Accelerator Pilot, this European programme enabled her to secure a €2 million grant.

In 2021, we managed to raise €7.3 million from the French Deposit and Consignment Office (Caisse des Dépôts et Consignation or CDC), the European Commission’s EIC and EIT programme and industrial partners.

Antofénol was then successful in the national call for proposals for the “Plan de Relance pour l’industrie – secteurs stratégiques” (Recovery plan for Industry – Strategic Sectors). With the support of the Vaucluse prefecture and the French government’s economic services, as well as that of the South Provence-Alpes-Côte d’Azur region and local partners, we have received €6.8 million in aid, which represents more than 15% of the total investment and is the largest amount granted to date.

In 2022, we also welcomed Demeter IM into our capital, via its VitiRev Innovation Fund, enabling the original Business Angels to make a positive departure.

Our CEO, Fanny Rolet, explains:

Demeter IM is the first VC fund to join the Antofénol adventure. Their experience in investing in young companies with industrial ambitions will enable Antofénol to consolidate the next stages of its development. The nature of the VitiRev Innovation Fund, involving pioneering wineries, shows the desire of the agricultural world to adapt to the societal and environmental issues of tomorrow. As a major stakeholder in private equity for the ecological transition, Demeter IM is rooting Antofénol’s approach into a tangible reality for other stakeholders in society who wish to offer a sustainable agricultural future by developing biocontrol products.

Assisted and supported in our ambitions, it will be our turn in the future to support the agricultural, cosmetics and food sectors on an industrial scale. Being able to offer potent, effective and natural functional ingredients to our customers, while at the same time being profoundly respectful of nature, will be a key milestone in our mission.

26 January 2023

23 November 2022